A closer look at one of Shenzhen Machine Screw Parts Inc.'s honored departments

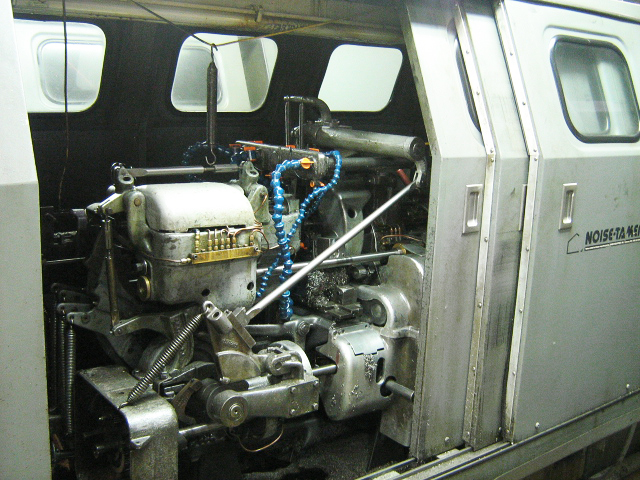

The Davenport Automatic Screw Machine has been recognized for decades past as the right solution for an endless variety of high volume turned parts produced from bar stock.

Our Davenport multi-spindle screw machines were used to produce products from bar stock ranging from 1/16" to 3/4 " in diameter, in materials ranging from brass and aluminum to cold drawn steels and even plastics. Being a multiple spindle screw machine, their production volume applications tended to be for runs of at least 10,000 pieces.

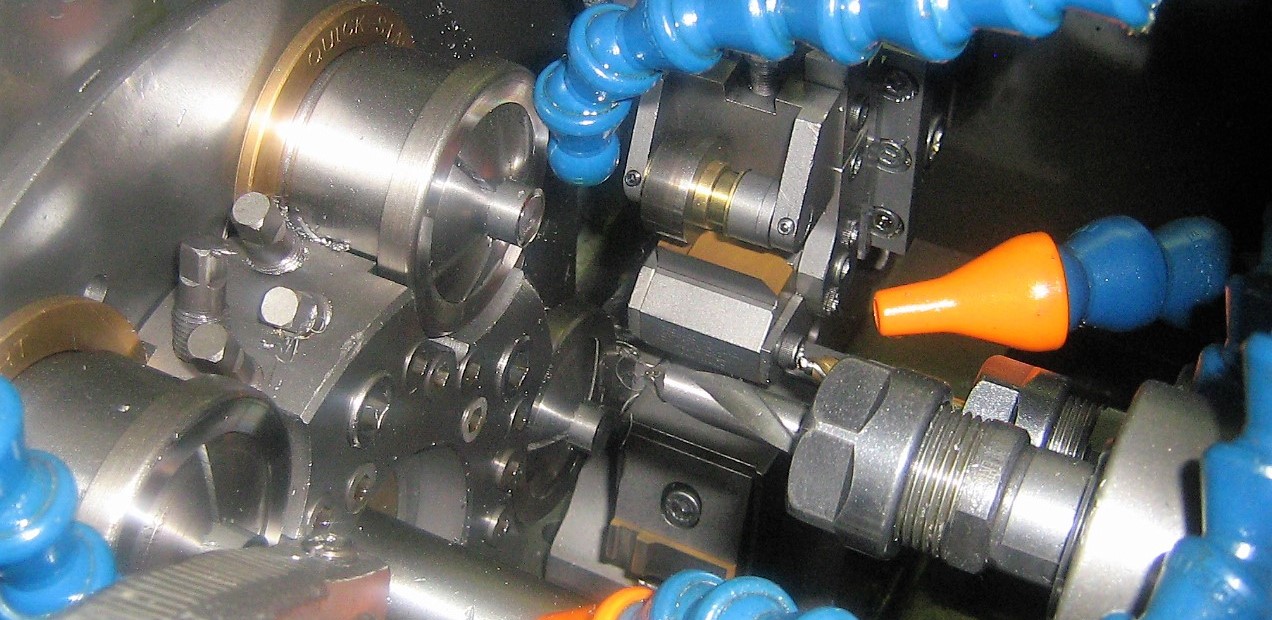

A wide diversity of specialty attachments were available for these machines and often allowed for the production of a very complex parts at very high speeds. Over the years the basic design of the multi-spindle screw machines had not really changed, but the tooling applied to the machines, with quick change holders and high-performance tools, drove their productivity to new levels.

Shenzhen Machine Screw Parts Inc. had also developed a propriety PLC process control interface that had proven to yield both better quality and greater efficiency. We utilized these machines for the production of many millions of parts.

We retired these iconic screw machines in the late 2000s and have since transitioned to Tornos precision multi-spindle automatics.